Injection Mould Toolmaking

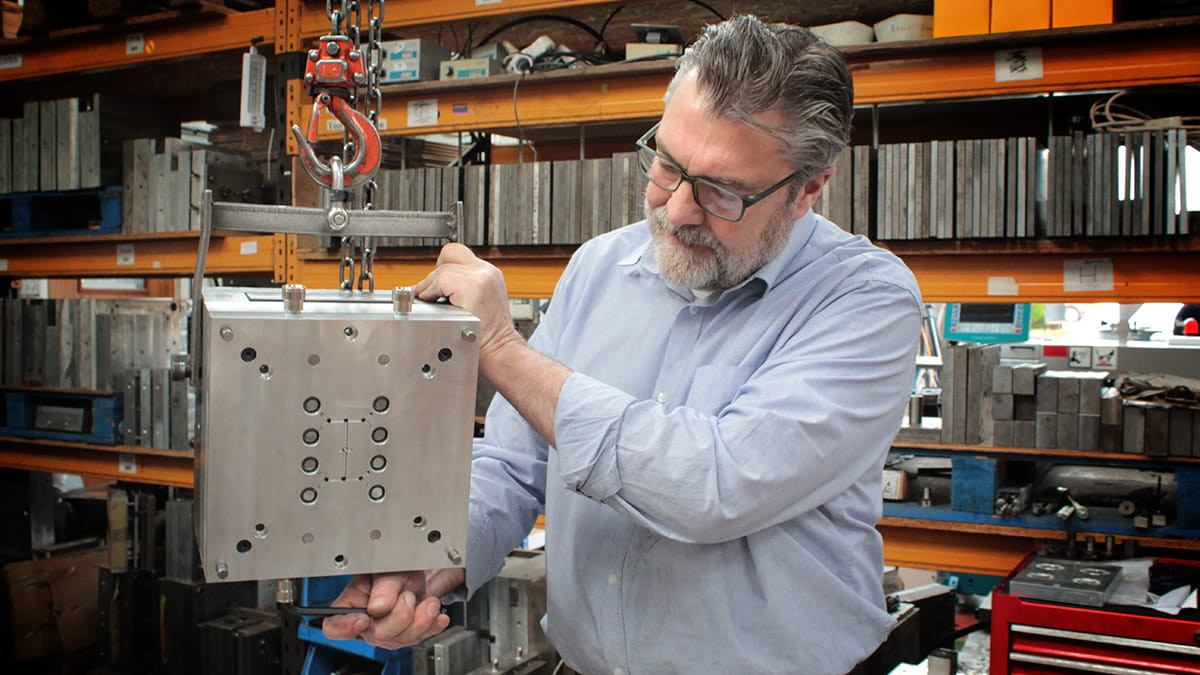

With over two decades of expertise, Great Central Plastics has revolutionised injection mould tool production, transitioning from slow and costly traditional methods to cutting-edge computer-based operations. We are dedicated to meeting customer demands by continually investing in state-of-the-art machinery and software.

Our injection mould tool room operates a modular insert system, utilising various high-quality metals such as aluminium, P20 steel and hardened steel. These are renowned for use in prestigious industries like Aircrafts and F1 cars. This innovation enables faster tooling and accelerated cycle times during moulding. By incorporating inserts within our extensive range of bolsters, we ensure minimal setup costs for bespoke projects, making a minimum order quantity (MOQ) of 250 highly viable for simple jobs.

For intricate and complex products, we offer fully owned, dedicated steel bolsters with intricate split lines and fully hardened core and cavity details. Our tools are meticulously designed and can incorporate side-action movements if required.

At Great Central Plastics, we provide an array of options for feed points, ranging from conventional edge gates and sub-gates to full hot runner systems. We tailor our choices based on your product, budget, and cavity layout, ensuring optimal results.

Understanding the importance of selecting the right material for your mould tool, we offer guidance on commonly used mould materials:

Aluminium: Ideal for low-volume projects involving general-purpose plastics, such as PP, ABS, PE, and nylon. It presents a cost-effective option.

Pre-hardened steel (P20): Widely used and suitable for low to medium-volume projects, offering excellent durability and versatility.

Through-hardened steel (H13): Employed for high-volume projects, complex tools, and abrasive materials, providing outstanding hardness and durability.

Corrosion-resistant steel (Stainless): Recommended for high-volume projects, particularly when surface finish is crucial, offering corrosion resistance.

By choosing the appropriate material, you can enhance performance and prolong the lifespan of your production mould tool, avoiding unnecessary maintenance expenses and production interruptions.

At Great Central Plastics, we take pride in our comprehensive maintenance services. Our team ensures routine maintenance for all the mould tools we manufacture, and any necessary repairs are undertaken free of charge during the lifespan of the tools while we handle the moulding of your products. This commitment offers peace of mind, eliminating additional expenses beyond the initial tooling investment.

Additionally, we understand the value of your existing injection mould tools. If you have a tool made elsewhere in good working order, we can modify it to ensure compatibility with our injection moulding machines. Before commencing mass production, we will run samples to guarantee your satisfaction with the tool's condition and the quality of the moulded products.

For more information on our injection mould toolmaking services and how we can help bring your vision to life, contact us today. Choose Great Central Plastics for unmatched expertise and cutting-edge solutions.

FAQs

Soft tooling is where a flexible material such as silicone is used as the tool material for use with case urethane moulding.

Whilst being a more flexible tool and therefore more cost effective to produce, soft tools wear out much faster than hard tools and lend themselves for low volume items (typically under 30 per tool) such as complex prototypes.

Soft tooling isn’t something we offer at GCP and instead for prototyping we suggest 3D printing.

Hard tooling on the other hand is used for producing high volume plastic items via injection moulding. Hard tooling materials are much more durable such as aluminium, steel or nickel alloys.

Although the initial startup cost is higher than soft tooling, once up and running, hard tools can withstand production cycles of items in the millions. This can be more cost effective overall.

Tooling, in relation to plastic injection moulding is the mould or ‘template’ created for mass production of plastic items and often referred to as machine tooling.

The tooling process is made up of 3 stages:

Injection and distribution of molten plastic

Cooling into the final solidified product

Ejection of the finished product

The process often requires high-quality engineering to design the negative cavity space for injecting the molten (liquid) plastic to form into plastic products.

Cooling time, sensors and tolerance levels are just some of the complexities involved in the tooling design process.

Get a Quote