Painted Badges

What are Painted Automotive Badges?

Automotive badges are a common sight on cars, trucks, and motorcycles. These small, often decorative emblems can carry a lot of significance, representing a vehicle's brand, model, or features. While the majority of badges are manufactured using plastic injection moulding, they are often further customised and enhanced with a painting process.

Automotive badges are typically made from plastic materials, most commonly ABS (Acrylonitrile Butadiene Styrene), and come in various shapes, sizes, and complexities, depending on the manufacturer and the intended application.

To elevate the appearance of these moulded components and provide a choice of colour and surface finish, they are commonly spray painted, applying a layer of paint to the plastic surface to create a permanent aesthetic improvement.

How are Painted Automotive Badges Manufactured?

Spray painting plastic injection moulded automotive badges is a multi-step process that involves precision and attention to detail. Here's an overview of how these badges are painted:

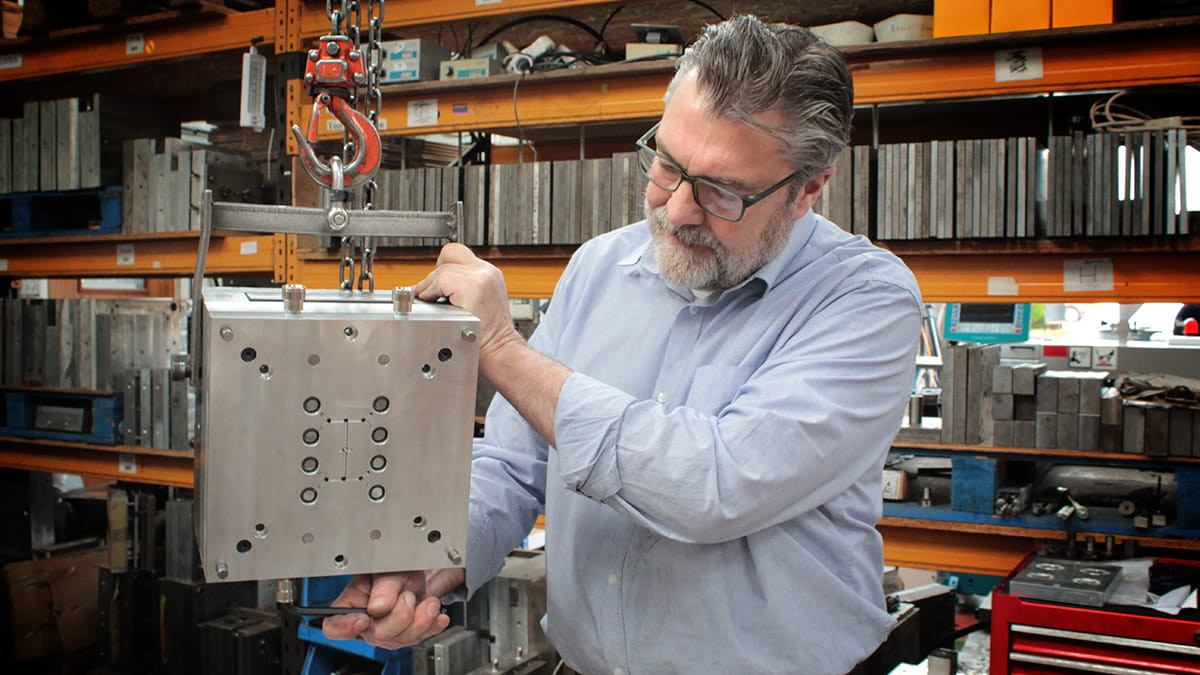

Badge Production: The process begins with the manufacturing of plastic injection moulded badges. This is done by injecting molten plastic into a mould cavity designed to the desired badge shape. Once the plastic cools and hardens, the product is ejected from the mould, and the basic badge is ready for further processing.

Surface Preparation: Before painting, the badges must undergo surface preparation. This typically involves cleaning and, in some cases, priming the plastic to ensure proper paint adhesion. The exact method may vary depending on the type of plastic and the paint used. Failure to prepare the surface for painting can have a detrimental effect on the car badge's durability.

Painting: The badges are painted using a spray painting technique. Here's how it's done:

a. Masking: Any badge areas that shouldn't be painted are carefully masked using tape or other masking materials. This ensures that the paint is applied only to the desired areas.

b. Spray Painting: A spray gun is used to apply a thin and even layer of paint onto the badge's surface. Automotive paint is designed to be durable and resist fading, making it an ideal choice for this application.

c. Drying: After painting, the badges are left to dry in a controlled environment. This allows the paint to cure correctly and achieve the desired, permanent finish.

Quality Control: The painted badges undergo a quality control inspection to ensure that the paint is even, has adhered properly, and matches the customers' desired colour and finish. Any imperfections are corrected before the badges are considered ready for use.

How Does Painting Differ from Chrome-Plating?

Painting is typically a more expensive process because it is more labour-intensive than chrome plating. However, it can offer higher flexibility in design compared to chrome-platings single type of finish.

Spray painting opens up an infinite number of designs, as any colour can be used, and in a gloss or matte finish.

PAINTED AUTOMOTIVE BADGES AT A GLANCE

- UK-MADE

- WEATHER RESISTANT

- HIGH LEVELS OF CUSTOMISATION

Painted Automotive Badge Applications

Brand Identification:

One of the primary applications of injection moulded painted badges is for displaying the brand logo on the front grille, rear, steering wheel, or other prominent locations in a vehicle. This helps instant brand identification and contributes to the overall brand image of the manufacturer.

Model Differentiation:

Automotive manufacturers often use injection moulded painted badges to denote specific models within their line-up. These badges may include model names or numbers and are strategically placed on the vehicle to assist consumers in differentiating between various models.

Customisation:

Car enthusiasts and owners frequently opt for customised automotive painted badges to add a personal touch to their vehicles. These custom badges can feature unique designs, colours, or even personal messages, allowing owners to express their individuality and style.

Collector's Editions and Limited Runs:

Vehicles produced as part of limited production runs or collector's editions often feature injection moulded painted badges to highlight their exclusivity. These badges may have unique colours, materials, or design elements to signify the vehicle's rarity. Traditionally favouring chrome finishes, some high-end car ranges now opt for badges and crests with a matte-black finish, adding a touch of luxury.

Regulatory Compliance:

Some injection moulded badges may include information related to regulatory compliance, safety standards, or environmental certifications. These badges serve as a visual indication that the vehicle meets specific industry or governmental requirements.

Experience the Great Central Plastics Difference

When you choose Great Central Plastics, you gain a reliable partner committed to delivering exceptional results that can guide you throughout every step of your manufacturing journey.

Our expertise in bespoke injection moulding, cutting-edge technology, wide material selection, and customisable finishes ensures that your unique requirements are met with the highest levels of sustainability, precision and excellence.

With minimum order quantities as low as 100 for bespoke wheel caps and automotive badges (depending on final design), the Great Central Plastics team is flexible, experienced and ready to discuss your automotive moulding project.

Contact us today to discover how our bespoke injection moulding services can bring your vision to life.