Resin Decals

What are Resin Decals?

Resin decals, commonly referred to as domed stickers or resin stickers, are a specialised type of custom badging distinguished by their three-dimensional, raised appearance. This unique visual effect is achieved by applying a substantial layer of clear polyurethane resin onto a printed design, resulting in a distinctive domed finish. This meticulous process imparts a premium and polished look to the badge designs, which are often applied to vehicles, electronics, or industrial equipment.

How are Resin Decals Manufactured?

Designing the Decal: Creating a personalised resin decal is an excellent way to infuse a distinctive flair into your automotive product. The first crucial step in creating a gel resin badge involves designing the decal. Utilising the latest graphic design software like Adobe Illustrator or Photoshop, we ensure the incorporation of high-quality images and vector graphics for optimal results.

Selecting the Ideal Material: The choice of material for your automotive resin decal is pivotal to achieving clarity, durability, and flexibility, coupled with weather resistance to withstand challenging conditions. Opting for a high-quality resin that is UV-stable and boasts a high gloss finish, steering clear of low-quality options that may turn yellow or become brittle over time.

Decal Creation Process: Crafting a domed automotive decal involves a series of meticulous manufacturing steps. Initially, we print your design on high-tack vinyl, recommended for rough surfaces. Subsequently, we employ a vinyl cutter to cut out the sticker precisely. Once the sticker is printed, cut, and dried, the next step is the application of resin.

The polyurethane resin is mixed thoroughly and then poured onto the sticker, ensuring an even spread. The resin needs approximately 48 hours to cure to solidify the domed effect.

RESIN DECALS AT A GLANCE

- UK-MADE

- FULL COLOUR BRANDING

- UV-STABILISED

Resin Decal Applications

Resin decals find versatile applications across various industries due to their unique properties and visual appeal. Here are some common applications for resin decals:

Automotive Industry:

Branding and Logos: Resin decals are widely used in the automotive industry for displaying brand logos and emblems on vehicles. They contribute to brand recognition and enhance the visual identity of cars and motorcycles.

Customisation: Car manufacturers and modification companies often use resin decals to add unique and customised elements to their vehicles. This customisation can include special editions, model names, or specific design elements.

Electronics:

Product Branding: Resin decals are applied to electronic devices, such as laptops, smartphones, and audio equipment, to display brand logos and product information.

Control Panels: In electronic appliances, resin decals may be used on control panels to label buttons and functions, providing a durable and visually appealing solution.

Industrial Equipment:

Warning Labels: Resin decals are utilised for creating durable and weather-resistant warning labels on industrial equipment. The protective resin coating ensures longevity in harsh environments.

Product Identification: In manufacturing settings, resin decals can be used for product identification, labelling machinery or components with serial numbers or specifications.

The Great Central Plastics Difference

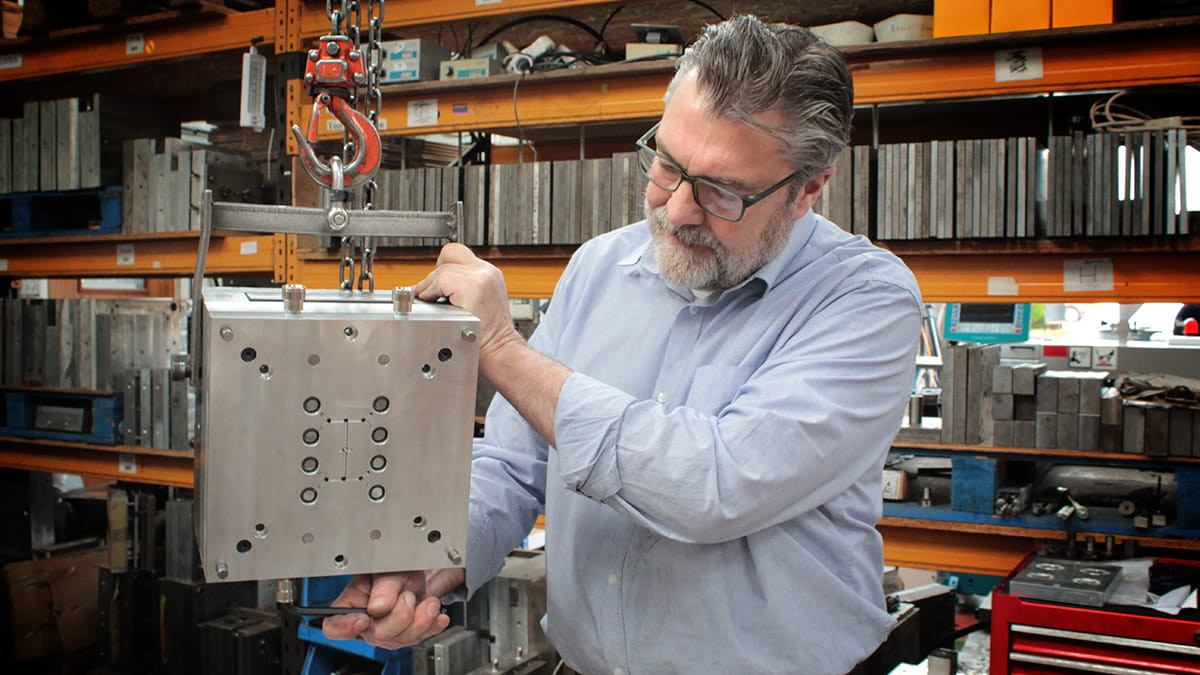

At Great Central Plastics, our commitment to elevating product quality extends beyond the application of resin decals alone. We take a comprehensive approach by integrating resin decals with injection moulded carriers, a strategic synergy that enhances the overall aesthetic appeal, durability, and functionality of the end product.

The injection moulded carriers serve as a robust foundation for the resin decals, providing structural integrity and seamless integration with the product. This fusion not only ensures a secure attachment but also contributes to the overall durability and longevity of the product.

As an experienced injection moulder, our processes allow for flexibility in the choice of materials for the carriers. Clients can opt for carriers moulded in virgin material, known for its purity, consistency, and superior quality. Or clients can choose an eco polymer to align with sustainability goals.

For those seeking a touch of sophistication, we also offer the option of chrome-plated carriers. This adds a reflective and polished surface, enhancing the visual impact of the resin decals. Chrome-plated carriers not only provide an additional layer of protection but also provide a premium finish, making them particularly appealing for high-end applications where aesthetics play a crucial role.

Our expertise lies in seamlessly integrating these two components – the resin decal and the injection moulded carrier – to create a harmonious and visually striking final product.

Discover the Great Central Plastics difference with resin decals. Contact us now!